Creality Ender 3

The Creality Ender 3 is arguably the best printer in the sub $250 price range. You can find it anywhere between ~$180-$250 depending on how long you would like to wait to receive the printer.

If you are wanting it sooner and are willing to spend a few extra dollars, you can head over to Amazon and pick one up for $235 at the time of writing. The benefits of choosing this route is that you can have it delivered in 2 days if you have signed up for Amazon Prime. If you do not have Amazon Prime, you can select to start a 30 day free trial and obtain all the benefits of prime for the duration of the trial.

If you are willing to save a few dollars and wait, BangGoods would be your best option. Sold and shipped from the US.

GearBest is another option. The downside is that the printer would be coming from overseas and there is a possibility that you would have to pay customs or duty fees on top. There is more of a possibility that your parcel gets lost also. I received a tracking link that went from GearBest’s warehouse to my front door so it wasn’t that bad. I personally did not have any problems with anything but you never know.

Recently, Creality has also released the Ender 3 Pro. The pro features a removable magnetic plate, a high quality Meanwell 500w power supply (though people have been reporting that they are getting 350w), the Y-axis frame has become beefier reducing the rare issue of wobbling, and the control box has been flipped upside down reducing the risk of foreign objects being sucked in to the fan. These upgrade come with a $100 price tag. you can find the Ender 3 Pro over at Amazon, BangGood, and GearBest.

Whichever option you choose, you will get a rock solid printer that will love.

When you get your shiny new printer, there are a few things you are going to need to do before you start printing objects. The first being building the printer itself. Now, you can try to use the included picture guide to do this, but it is absolutely horrible and hard to follow. So lets watch and follow along a video that NoLimits3D has made on YouTube:

This is the guide that I followed along with. The creator makes it very easy to follow along.

Now the first thing we should do is square the x-axis to the frame. This part isn’t strictly necessary, but it might save some headaches down the road. I have used this video as a guide to leveling the x-axis. The key thing here is that we are leveling the x-axis gantry to the frame of the printer and not the build plate.

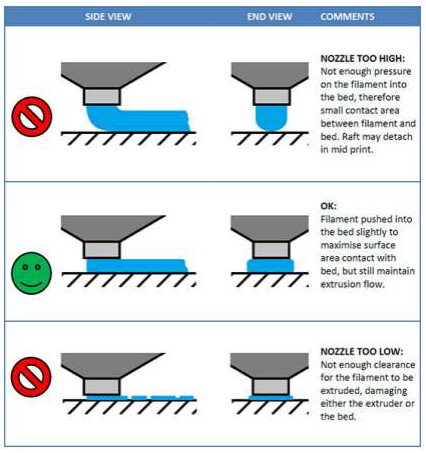

Now that the printer is set up and square, we get to start printing! Well, kind of… The first thing we are going to print are single layer squares so that we can level the bed through a method called ‘live leveling’. This means that we are going to be leveling the bed while we are printing. This video does a good job at explaining the process of live leveling. While you are leveling, if you have good enough eyes to look under the extruder, you can really dial in the leveling process by following the picture below as a guide.

Slicers

The next thing we need to work on is what slicing software that you want to use.

- Ultimaker Cura

- Cura is my main slicing software that has a lot of features and is completely free. If you don’t want to give your information just to download the software, you can select “I don’t want to share my information.” from the dropdown list while downloading. The only downside is updating the software as they do not provide an inline updater. This means that you would have to constantly go on their website, download the new build, and install it over the old build or uninstall the old and install the new. Sixteenbit has an awesome profile to get you started and I encourage you to give it a try.

- Simplify3D

- Simplify3D (S3D) is a premium slicer with a price tag of $149. While this is a very good slicer and the indisputable leader in slicing software for a while, there are drawbacks. Most slicing software is now catching up to S3D with features and quality. It seems that updates have come to a crawling halt. At the time of writing, the current version is 4.1. The last update before that was 4.0 in July 2017. That was a year and five months without an update. I personally have not used S3D, so I can’t comment on ease of use or features, but it is a popular option.

- Slic3r

- Slicer is a free and open source slicing software. Some of the features include auto mesh repairing, conversion to multiple file formats, Octoprint integration, and the ability to cut meshes. Again, I have not tried this software so I can’t comment on ease of use or how well it works.

Filaments

There are many different brands of filaments out there. It is important on what brand of filament that you buy because it can drastically change print quality. Here is a list of filament that the people over on the Sudomod Discord have used and rated:

= Good to use | = Use at your own risk | = Avoid

- Hatchbox

- Hatchbox is the brand that I use and have had zero problems with that was the filaments fault. They come in a very wide variety of colors. If you are ordering from Amazon, READ THE COMMENTS! Some colors have had other companies hijack the listing and send an off brand filament. Amazon and Hatchbox have been working on fixing the listings and have been very good to the customers that received the wrong filament. Hatchbox’s main site.

- Amz3D

- Rotiik over on the Sudomod Discord has used this extensively and highly recommends this brand.

- Inland

- Recommended by Littleferris on the Sudomod Discord.

- Prusament

- Prusament is a premium filament made by Prusa. They have some awesome different filaments like their Galaxy Black that has some type of glitter in it to make your prints sparkle. Their filament has a strict standard and comes with a QR code that you can scan to see when it was made and the tolerances.

- Push Plastic

- This is the filament that Wermy over on Sudomod uses

- Amazon Basics

- While some have had good experiences with Amazons brand of filament, others have not. Use at your own risk.

- Fillamentium

- This has been mentioned in the Sudomod Discord but there are no reviews on it. Manufacturer’s website.

- Polyalchemy

- This has been mentioned in the Sudomod Discord but there are no reviews on it.

- MakerGeeks

Troubleshooting

If you are having problems with your printer, being leaking filament, weird prints, etc, here is a really helpful troubleshooting guide in pdf format that has an answer for a multitude of problems and questions. If you are still having problems, you can always ask in the #3d_printing channel of the Sudomod Discord.

Printed Recommendations

These are my recommendations of things to print to make the Ender 3 even better. Some of these things will help with prints, some will help with safety, and some with aesthetics.

Strongly recommended

- Petsfang Bullseye Fan Duct

- The bullseye air duct replaces the original duct. The benefit of the Bullseye is that it delivers air to both sides of the print instead of only one side producing better quality prints. This mod does require a few extra parts to pick up from the hardware store but are easy to find. This also opens up the front so you can see the print better. The only two parts you need to print are the “BULLSEYE_BASE_CREALITY_x.xx” and “Bullseye_Duct_x.xx”. There are additional STLs for physical upgrades such as the EZ ABL or BL Touch.

- Hero Me Fan Duct

- The Hero Me fan duct is an alternative to the Bullseye that produces about the same results as the Bullseye. One advantage of this system over the Bullseye is that it uses the factory provided screws. This system also has extra STLs to attach an EZ ABL or BL Touch. This system also has STLs for the stock 4010 cooling fan or an upgraded 5015 cooling fan.

- Fan Guard

- If you have the non pro version of the Ender 3, this is an absolute must to print. This is a guard that will stop objects from falling down in the control board fan. If that fan seizes up from objects falling in to it, it could stop working and cause damage to the control board from overheating. There are multiple versions of this fan guard. You can see a fee designs from my collection or search for another one that you like.

- Z-Axis Spacer

- A lot of Ender 3s are plagues with a binding on the Z-axis. Luckily, this is pretty easy to fix. Just print these out and place them in between the stepper motor and the frame. This should fix any binding problems that you have.

- Filament Guide

- This is a simple slide on filament guide that helps keep any filament away from the Z-axis lead screw. There are a few different types like with a wheel and bearings, but I found this one to be simple and effective.

- PTFE Pressure Fitting

- This small clip helps with the problem with the PTFE tobe moving. It keeps the pressure fitting from depressing and locking the PTFE tube in place. Though this helps, many people, including myself, have needed to upgrade their couplings to ones that aren’t absolute junk. You can find the fittings in a section below. (Thanks to Blaablaaguy from the Sudomod Discord for the suggestion.)

- Cable Anti Snag System

- Sometimes the cables that go from the control box to the bed will snag on the 2020 extrusion frame causing a layer shift during the print. This obviously is not good. There are many different methods to fix this:

- Cable chains: This is the method I used because I think it makes everything look nice and neat. I used 15 links for the bed and 15 links going to the gantry. The gantry won’t go all the way to the top with 15 links but it still serves the purpose as an anti snag device.

- Cable Clip: This is a simple yet effective clip that will keep the gantry cables close to the Z-axis stepper motor. This however does not prevent the cable going to the printing plate from snagging.

- Anti Snag Endcap: This is a simple mod that gets placed at the end of the 2020 extrusion. The theory is that the cable glides over the arc to prevent snagging. This is not a fool-proof method but yrmv.

- LCD PCB Cover

- This is a print that covers the bare LCD PCB. More of a safety thing but also makes it look nicer.

Other Mods

- Ribbon Cable Clip

- This clip keeps the ribbon cable (and my LED power cable) nice and tidy to the frame of the Ender 3. This clip will work on any 2020 extrusion frame. Not only does this keep the ribbon tidy and out of the way, but it also protects it if you decide to put a drawer/shelf system in that slot.

- Pi 3 Case

- If you are adding a Raspberry Pi 3 to use Octoprint, I would recommend printing a case to hold it. There are many cases that you can print for the Raspberry Pi 3. This is the case that I printed because it has 2020 rail mounting and lets me add a fan if needed. I placed it on the right side of the printer under the power supply for easy access.

- Tool Holder

- As you can see, there are many variations. Just a nice place to keep all of your tools in one place. You choose the one you like and go with it. I personally opted for a drawer/shelf.

- Drawer/Shelf combination

- I use the drawer to hold all the extra parts and tools that came with the Ender 3. The shelf is mainly used for temporary things like the clips that hold the build plate when I have to take it off for whatever reason. The glory about this combination is that they work well with the ribbon cable clips mentioned above.

Advanced Modifications

- Adding LED Lights to your printer

- This advanced modification will light up your prints. Useful to have consistent lighting for time lapses and monitoring prints while it’s dark.

- Powering a Raspberry Pi from the PSU

- This modification allows you to power a Raspberry Pi from the PSU. Useful for freeing up a plug but I personally find it annoying to shut down the Pi every time you want to turn the printer off.

Benchmarks and Further Refinement

- Benchy

- The most widely known and used benchmark print. Also makes a great gift or desk piece.

- XYZ Calibration Cube

- This benchmark allows you to calculate how accurate your printer is. If your printer allows it, you can calibrate your steps/mm.

- Calibrating e-steps

- Speaking of calibrating your e-steps… This is a guide on how to do exactly that! (Thanks J4red.)

- All in One Test

- This all in one test tests many things including overhangs, small objects, pillars, and many more things.

- Temperature Tower

- This test will test different things such as overhangs and objects at different temperatures so that you can dial in the perfect temp for your filament. This print takes a while to set up because you need to change the temperatures in your slicer to run the test properly.

Physical Upgrades

- MKS Gen L with TMC 2208 Stepper Drivers

- The MKS Gen L combined with the TMC 2208 stepper motor drivers are both REALLY GOOD upgrades for the Ender 3. The MKS Gen L motherboard replaces the stock MELZI one which includes a bootloader, scokets to install things like a BLTouch and filament runout sensor, and upgraded stepper motor drivers to quieter and more feature rich ones like the TMC2208. I HIGHLY recommend this upgrade if you are wanting a more quiet printer, or plan on adding any modifications like a BLTouch. You can find a guide on installing this board here.

- BL Touch by ANTCLABS

- The BL Touch is a bed mesh leveling sensor that will detect and correct any tilt in the printing bed during printing. This will work on any build surface such as glass, PEI, metals, etc. This is an advanced modification because you will also have to update Marlin (the firmware of your printer) to run the BL Touch. ANTCLABS is the original creator of the BL Touch and deserves every bit of support. Please buy from original creators and not the knockoffs. Teaching Tech has made a guide for the vanilla Marlin firmware and for the TH3D unified firmware.

- EZ ABL

- This is another common auto bed leveling kit that is out there. Same process is needed in that you need to update the firmware. Teaching Tech has made an installation guide on how to add the EZ ABL to your Ender 3.

- Gizmo Dorks PEI Sheet

- This is what I am currently using on my Ender 3. This is a sheet of PEI that makes the base of your prints have a smooth surface instead of the gritty one from the stock build plate. Prints come off easily once the build plate is cooled. You do not need to add any adheisives and cleaning is a simple wipe down with isopropal alcohol. Since this does not come in 235×235 mm size, you will need to go for the 254×254 mm (10″x10″) size and cut it down. I took calipers, locked them at 9mm and scored the protective sheeting. I then used a dremel with a cutting wheel to cut it down to size. If you have access to a table saw, that would be your best solution. A band saw would work also.

- Creality Ultrabase

- The ultrabase is a build surface that works very well while hot. Once this build plate cooled down though, this plate makes prints easy to pull off with two fingers. To clean, all you need is a quick wipe with rubbing alcohol and the print surface will act as new.

- Wham Bam Flexable Build Plate

- The Wham Bam build plate is a magnetically removable build plate which is made from PEX. PEX is more durable than PEI and does not need any additional adheisives like glue or hair spray. When your print is finished, you take the top layer off, bend it slightly, and your print will pop right off. Teaching Tech made a video reviewing the Wham Bam build plate and recommends it for those looking for an upgrade.

- Easy-Peelzy

- The Eazy-Peelzy is a magnetic print bed surface that you can take off the print bed when a print is finished and bend the surface to release a print. This method works well but does have problems with higher temps of heated beds as with any other magnetic method. You will need to order a larger size than your bed and cut it down.

- Capricorn PTFE Tubing

- This tubing would replace the stuck bowden tubing. The interior of the tubing has much less friction which makes it easier for the extruder to push filament of the bowden tube. Word to the wise, do not cut this tube with scissors. Use a very sharp object to slice through the tube without crushing it. Also recommended to keep the cut as straight as possible. Also available from Capricorn. Kit form with PTFE fittings and cutter.

- Capricorn PTFE Fittings

- The stock fittings on the Ender 3 are crap. They don’t hold the PTFE tube snug enough and slip all the time. It is recommended to replace them. This is a kit that gives you both ends that you need to replace them on the Ender 3 along with most other Creality printers. Kit form with 1 meter PTFE tubing and cutter.

- Bondtech Extruder

- Replacing the extruder can be a major upgrade to your printer. The Bondtech extruder is more accurate than the original that comes with the Ender 3. Replacing your extruder can also allow you to increase your feed speed, print speed, and accuracy thus reducing print times and producing cleaner prints. Also available on Bondtech’s website.

- 12v Noctua Fan

- This is the fan I used to replace the hot end fan when it was getting ridiculously loud. Noctua fans are very high quality and quiet. The only problem is that the power supply supplies 24v power and the fan runs at 12v. We will need to use a buck converter to step down the power to the required 12v. You can find a guide on how I achieved this here. I will be writing a guide on how to replace the fan shortly.

- Hotend Silicone Sock

- This replaces the ugly yellow insulation that comes stock on the hotend. Not really sure if it serves a functional purpose, but it does look way better.

- Nozzle Variaty Pack

- It never hurts to have extra nozzles on hand as they do wear out over time. This is a variety pack that goes from .2mm up to 1mm. The advantage of larger diameters is the ability to create stronger prints.

Flashing a Bootloader

The benefit of flashing a bootloader to your Ender 3 is so that you can update your firmware such as Marlin or TH3D. The advantage of flashing a custom firmware is that you can add advanced features like the BL Touch, disable features that you don’t use, and gain safety features like thermal runaway protection. The real only main drawback is that you would lose print resume, but since the firmware is open source, it is only a matter of time before it gets added back with thermal runaway protection. There are 3 main ways that you can flash a bootloader, all of which require an extra purchase:

- USBasp

- The USBasp is the cheapest option hardware wise to flash a bootloader to your Ender 3. My only concern is that you really won’t be able to use this board again unless you are a hobbyist and can use it to program multiple things. There is a great guide by MAT1UK 3D PRINTING that you can follow to update your Marlin firmware using this device. (Thanks to J4red from the Sudomod Discord for the suggestion.)

- Arduino Uno

- While this is not as cheap as using the USBasp, but seems to be the easiest method for flashing the firmware. This board can also serve multiple purposes and you can easily use it in multiple projects as well. You will also need a few GPIO jumper wires to connect the Arduino to your Ender 3 mainboard. Teaching Tech’s guide is a good step by step visual guide to flashing your firmware of choice.

- Raspberry Pi 3B+ | Raspberry Pi 3B

- I like the Raspberry Pi method of flashing a bootloader because you can then repurpose the pi to run as an Octoprint server. The downside is that this is the most technical and you need to be comfortable using a CLI to be able to flash the bootloader. This method will also require you to have some female to female GPIO jumper wires on hand to connect the Pi to the Ender 3 mainboard. Because I was unable to find a quality video guide on how to use this method, we will be using a written guide on Fission 3D.

This is meant to act as a collection for the Ender 3. If you have any suggestions or corrections to add to this list, feel free to drop it in the comments below.

amazon Amazon Associates Program

As an Amazon Associate, I earn from qualifying purchases. There is no extra cost to you.